Description

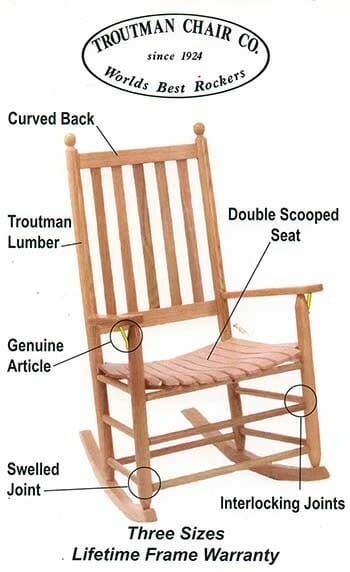

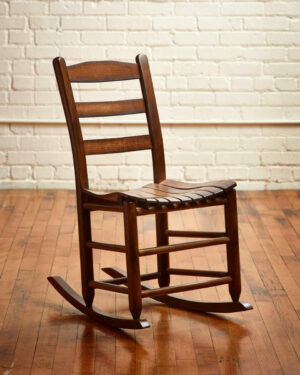

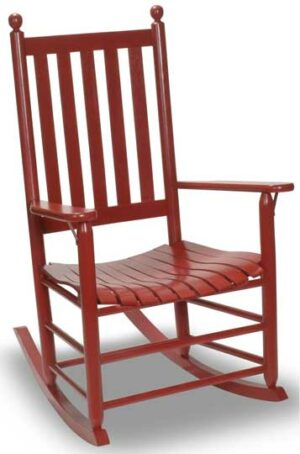

Plantation Shaker Rocker (930) by Troutman Chair Co.

Troutman Rockers are trademarked and are the only rockers of their kind. Made from a combination of Oak and Hickory, these rockers are handmade and built to last a lifetime. Produced in North Carolina, the 930 Plantation Shaker Rocker works perfectly on your covered porch or patio. Enjoy a finely crafted rocker that can be passed down from generation to generation.

About the 930 Plantation Rocker:

Bountiful in comfort and room, the 930 Plantation Rocker features curved back supports for spinal comfort. The largest of our rockers, this one includes a wide, double scooped seat, a tall back height, and broad splayed arms for ample room. It is one slat wider than our 430 rocker. In addition, the posts are thicker than a traditional rocker and has a more stout feel. These rockers ship unfinished or in a variety of beautiful, custom finishes. Finished in a water-based urethane, these rockers work best for outdoor use in a covered area. Minor assembly needed in order to attach the runners to the rocker. Please use the instructions and nails included with the runners in order to avoid injury.

Made in the USA

Click HERE to Shop all of the Quality products from Troutman Chair

Dimensions

Dimensions:

- Back height from floor to top of post 48″

- Seat height 16 ⅜” at rest

- Seat 24″ at the widest point and 18 ⅞” deep

- Arms 3 ⅝” wide – splayed to give more inside room

- Inside arm dimensions widest point at front 21 ⅜” – back is 18 ¾”

- Dimensions from to back 31″

- Widest point 28 ½”

- Weight 32 lbs.

Shipping Info

Shipping Information:

- The 930 rockers ship assembled (with the runners removed).

- As a result, they are too large for FedEx or UPS and are much safer being shipped on a pallet via freight carrier.

- For a quote, proceed to checkout and select the “R+L Carriers” option under shipping.

- We also offer FREE pickup from our store in Wilmington, North Carolina.

Specifications

Specifications:

- Solid Hardwoods

- Painted Finishes – Ash, Maple, Birch, Hickory

- Stained and Ready to Finish – Oak, Hickory

- Mortise and Tenon Construction, Shaker Techniques, interlocking joinery and swelled joint construction.

- Available Unfinished or Finished with stain (natural) or custom paint: Cotton Candy, Summer Sky, Black, Charleston Green, Geranium Red, Haint Blue, Hunter Green, Navy, New England Green, New England Yellow, Seaside, White

Troutman rockers are constructed and finished for use under cover if outdoors.

Wood Species

Oak logs are brought on-site from local loggers and then milled at Troutman Chair’s own sawmill making us one of the last vertically integrated furniture manufacturers in the United States. The wood is cut to dimension, stacked, and dried. Due to the nature of construction, no glue is found in a Troutman product.

Manufacturer Info

Troutman Chair Co., established in 1924, has been family-owned since its inception. The Brown family of Troutman, North Carolina is responsible for starting and maintaining the quality manufacturing process of solid wood furniture for almost three-quarters of a century.

In 1999, Champ and Jean Land purchased Troutman Chair Co. continuing the tradition of handcrafted furniture in the same manner established back in 1924 – with farmhouse, shaker-style chairs, rockers, stools, and tables. A true family-run business, the Land’s son Cam is now a driving creative force.

A Tradition of Excellence

Since 1999 the Land family has made few changes to the Troutman Chair Co. business and products. The goal of purchasing a company already manufacturing the best product in its category and enjoying a near-perfect reputation was to merely enhance the best and offer it to the rest of the country: Troutman products were historically sold only in the Southeast. Troutman now ships anywhere in the continental United States and as far as Germany. Minor adjustments were made to the products over time – the Lands added a deluxe finish line with stain and painted finishes. They moved to stainless steel nails and arm braces to avoid rusting. Since taking over, the Lands have expanded the product catalog and continue to look for new ways to bring quality made wood products into customers’ homes, on front porches, resorts, and in unique places like airports.

You may also like…

-

146 Cottage Rocker

From: $199.99 Quick ViewSelect options This product has multiple variants. The options may be chosen on the product page146 Cottage Rocker

From: $199.99

-

Oak 430 Classic Jumbo Rocker

From: $269.99 Quick ViewSelect options This product has multiple variants. The options may be chosen on the product pageOak 430 Classic Jumbo Rocker

From: $269.99

-

7 Aunt Annie’s Rocker

From: $179.99 Quick ViewSelect options This product has multiple variants. The options may be chosen on the product page7 Aunt Annie’s Rocker

From: $179.99

-

70 Side Table Troutman Chair Company

From: $119.99 Quick ViewSelect options This product has multiple variants. The options may be chosen on the product page70 Side Table Troutman Chair Company

From: $119.99

-

330 Coastal Rocker

From: $239.99 Quick ViewSelect options This product has multiple variants. The options may be chosen on the product page330 Coastal Rocker

From: $239.99

-

51 Oak Emilie Child Rocker

From: $89.99 Quick ViewSelect options This product has multiple variants. The options may be chosen on the product page51 Oak Emilie Child Rocker

From: $89.99

-

Oak 470 Classic Jumbo Lumbar Rocker

From: $299.99 Quick ViewSelect options This product has multiple variants. The options may be chosen on the product pageOak 470 Classic Jumbo Lumbar Rocker

From: $299.99

-

Oak 970 Lumbar Back Plantation Rocker

From: $349.99 Quick ViewSelect options This product has multiple variants. The options may be chosen on the product pageOak 970 Lumbar Back Plantation Rocker

From: $349.99